INTRODUCTION

Metal-ceramic restorations have been used in dentistry for over a century due to their excellent fracture resistance.1-3 Currently, base metal alloys have replaced the high noble and noble metal casting alloys by allowing fabrication of long span and cantilevered FPDs with lesser thickness and greater rigidity.4 Moreover, higher melting range reduces the risk of distortion and sagging of metal substructure during porcelain firing.5 Due to optimal mechanical properties, low density and cost considerations, base metal alloys are considered as a viable alternative to precious alloys in metal- ceramic restorations.6-8 However, restoration’s longevity depends on the bond strength between the metal core and the veneering porcelain. Residual stress gradients, interfacial chemistry, and the interfacial morphology are the main factors that influence the success of a ceramic-metal bond.9

Multiple firing procedures are usually necessary for the fabrication of metal-ceramic restorations to match the esthetics of natural dentition, especially when using the standard layering technique. It has been found that repeated firings of the base metal alloys enhance the formation of excessive oxide layers which could lead to fracture through the metal oxide.10 Furthermore, repeated firings may also produce changes in micro-crack density and partial decoupling of the leucite from the surrounding glass matrix, resulting in a lowering of the bulk thermal expansion of the porcelain.11 Large differences in thermal expansion coefficients may form residual stress gradients across the metal- ceramic interface during processing, with a subsequent decrease in bond strength.12, 13 Therefore, the purpose of the present study was to determine the effect of repeated firings on the shear bond strength of feldspathic porcelain veneered to conventional cast base metal alloys.

MATERIALS AND METHODS

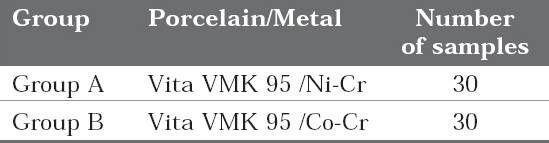

Feldspathic porcelain (VMK 95, VITA Zahnfabrik, Bad Sackingen, Germany) was fused to two base metal alloys - Ni-Cr alloy (Wiron-99, Bego Ltd., Germany) and Co-Cr alloy (Wirobond-C, Bego Ltd., Germany) to form two porcelain - metal groups (Table 1).

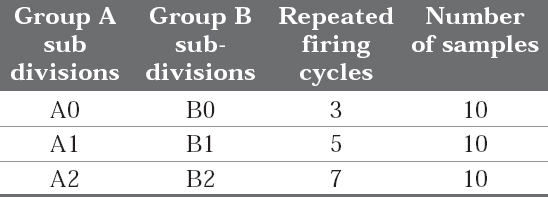

|

Table 1: Experimental groups division

Click here to view |

Preparation of cast specimens

A metal die was prepared according to the sample dimensions (cylindrical rod, 8mm in height; and 4mm in diameter) specified by de Melo et al (Figure 1) and its silicone index (Polyvinyl siloxane, Aquasil soft putty, Dentsply) was used to standardize the waxed parts for formation of the metallic aspect of the specimen.14 Sixty wax molds were made using inlay wax (Bego, Germany) and invested in a phosphate bonded investment material (Bellasun, Bego). Casting was done using centrifugal casting machine (OKAY PLUS, Galoni, Italy), through the lost wax casting technique, to obtain thirty correspondent metallic portion of the specimens for each alloy (Ni-Cr alloy, Wiron-99, Bego; and Co-Cr alloy, Wirobond C, Bego). Metal surface treatment was performed by degassing and grit-blasting the specimens with aluminum oxide (100μ) under 2-bar pressure for 10 seconds (Model Microjet II, EDG, Sao Carlos, SP, Brazil). The specimens were cleaned with tap water, isopropyl alcohol and then allowed to dry for 10 minutes.

|

Figure 1: Schematic illustration of specimen dimensions

Click here to view |

Veneering procedure

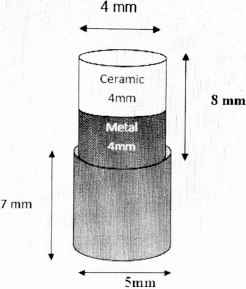

Two thin layers of opaque porcelain powder (VMK 95, VITA Zahnfabrik, Bad Sackingen, Germany) in a paste/liquid mix were applied on the metal specimens using a brush and fired according to the manufacturer’s instructions (Porcelain furnace, Vacumat 40 ; Vita Zahnfabrik, Bad Sackingen, Germany). Dentin porcelain was condensed to a height of 4mm in a slightly oversized silicone putty index to compensate for the contraction generated during the first firing cycle (Figure 2) and submitted to dentin firing to achieve the final dimensions of the samples as described in Figure 1. The specimens within each group were randomly divided into three subgroups and subjected to repeated firings as per manufacturers’ instructions (Table 2).

|

Figure 2: Silicone putty index to standardize porcelain application

Click here to view |

|

Table 2: Experimental group subdivisions

Click here to view |

Testing Procedures

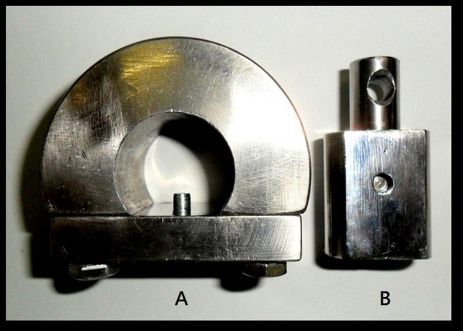

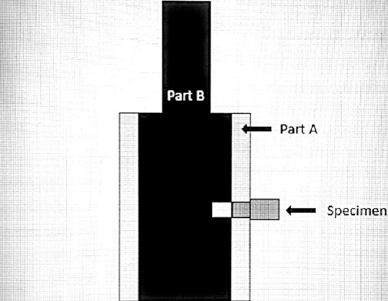

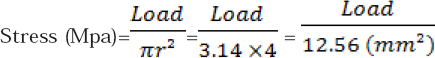

The mechanical shear bond test was performed using a custom made steel apparatus consisting of two independent parts (A and B), that concentrated the tension at the metal-ceramic interface. The Part A was cylindrical with a flat interior adaptation that enabled insertion of the other Part B, comprising of an upper cylindrical prolongation to serve as a piston during the mechanical evaluation of the specimens (Figure 3). The specimens were inserted into the apparatus through an orifice (4mm diameter) on the flat side of both the parts, that lodged the metallic portion of the specimen in Part A and the ceramic portion in Part B (Figure 4). The shear bond test was conducted in a universal testing machine (INSTRON 3366, Norwood, USA), with a 2500-kgf load cell that applied shear forces at the metal- porcelain interface at a crosshead speed of 1 mm/min until failure occurred. Failure loads were recorded in Newton (N) and results were converted into MPa using the following formula:

|

Figure 3: Custom made apparatus

Click here to view |

|

Figure 4: Schematic illustration of the position of specimen during testing

Click here to view |

|

Click here to view |

Statistical Analysis

One-way ANOVA test was used (p»0.05) for statistical analysis of the data. The mean values of the two groups were compared using student’s- t test. A statistical software package (SPSS 15.0; SPSS, Inc., Cary, NC, USA) was used for the analysis.

RESULTS

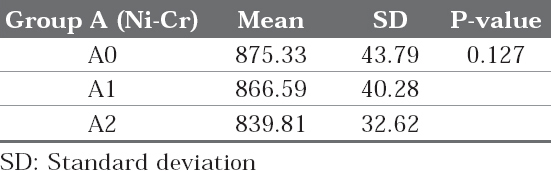

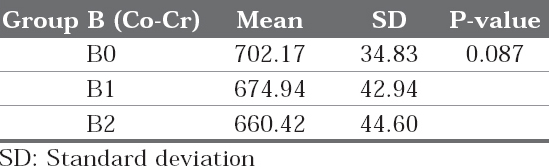

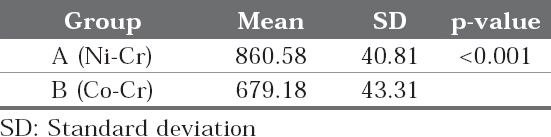

The mean bond strength values and standard deviations using the one-way ANOVA test are presented in Table 3 and 4. Results showed no statistically significant difference between shear bond strength values in the Ni-Cr/porcelain and Co- Cr alloy/porcelain combinations (p=0.05) after 3, 5 and 7 repeated firings. The Student t test results showed that Group A (68.52 MPa ± 40.81) had significantly higher mean shear bond strength value than Group B (54.07 MPa ± 43.31) (Table 5).

|

Table 3: One-way ANOVA for mean shear bond loads between the Sub-groups of Group A

Click here to view |

|

Table 4: One-way ANOVA for mean shear bond loads between the Sub-groups of Group B

Click here to view |

|

Table 5: Comparison of Mean shear bond loads between Group A & Group B using student-t test

Click here to view |

DISCUSSION

The suitable oxidation of metal and interdiffusion of ions between the metal and porcelain is believed to be the main adhesion mechanism in PFM restorations. Base metal alloys with nickel and chromium, form excessive oxide layers that may increase the risk of porcelain fracture.15 Mclean demonstrated that the coefficient of thermal expansion of vita porcelain was decreased due to nickel and chromium oxide and induced stresses, leading to failure of the non-precious metal- ceramic restorations.16 The thickness of oxide layer formed during the oxidation process depends on the alloy composition, preparation of metal and length of firing. It is common laboratory practice to remove some of the oxides before porcelain application by means of grit-blasting after de-gassing.17 Pask and Tomsia found that the amount of Ni2O and Cr2O3 was less at the metal-porcelain interface in the argon fired specimens than in the vacuum-fired ones.18 Barghi et al measured the fracture strength of repeatedly fired porcelain veneered to high noble and base metal alloy crowns and reported that multiple firings decreased the fracture strength in high noble alloys but did not significantly affect base metal alloys.10 The Selective laser melting (SLM) metal ceramic system showed improved porcelain adherence compared with conventional cast methods after 5 and 7 firings.19

In the present study, cast Ni-Cr and Co-Cr alloy were used to investigate the metal-ceramic bond strength after multiple firings. Various tests designed by researchers to evaluate bond strengths of different metalloceramic systems can be classified according to the nature of stresses created such as shear, tensile, flexural strength, torsion or a combination of the previous.20 Although, no single test method can be universally considered to be the most valid for clinical implications, shear tests are widely used because of its relative simplicity of use, ease of specimen preparation and rapid production of test results.21, 22 The base metal alloys mostly indicate a predominance of interface failures, suggesting a weak oxide layer at the metal-ceramic interface.23 Therefore, in the present study shear bond strength was tested through a custom made apparatus to direct the tension mostly to the metal- ceramic interface. Although, different values of bond strength are expected with different testing modes, the minimum of 51 MPa has been suggested as lower limit for bond strength.24 Multiple firings (3, 5 and 7) had no significant effect on shear bond strength of both the test groups. The mean shear bond strength of Ni-Cr alloy group (68.52 MPa) was higher than the Co-Cr alloy group (54.07 MPa). However, an advantage of Co-Cr alloys over Ni-Cr alloys is its great biocompatibility relative to the allergenic potential associated with beryllium and nickel.25 Therefore, cobalt-chromium alloys can be used as a suitable base-metal alternative for patients allergic to nickel. Further evaluation of the effects of other parameters such as different firing temperatures and thermocycling immersion times, on alternative alloys used in metal-ceramic restorations is required before making any clinical recommendations.

CONCLUSION

Within the limitations of this study, selected cast base metal alloys and veneering porcelain combinations were found to be suitable for clinical use as repeated firings did not significantly affect the metal-ceramic bond strength.